This is an old revision of the document!

Table of Contents

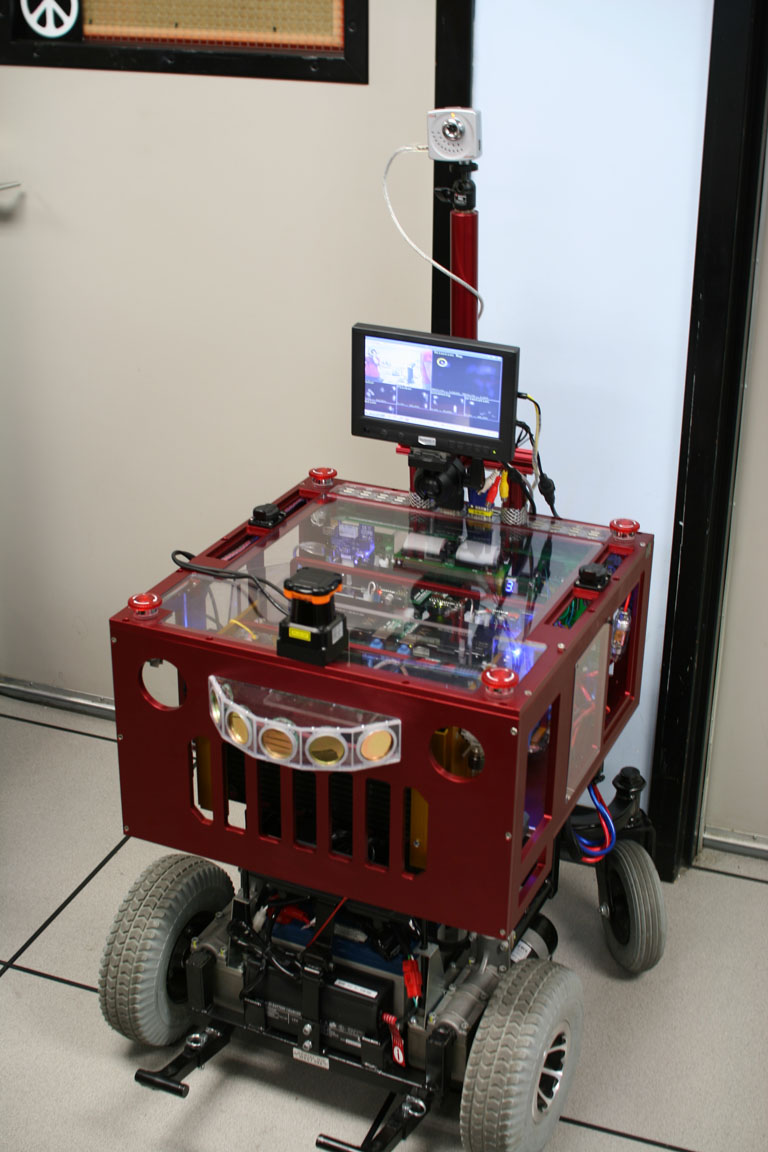

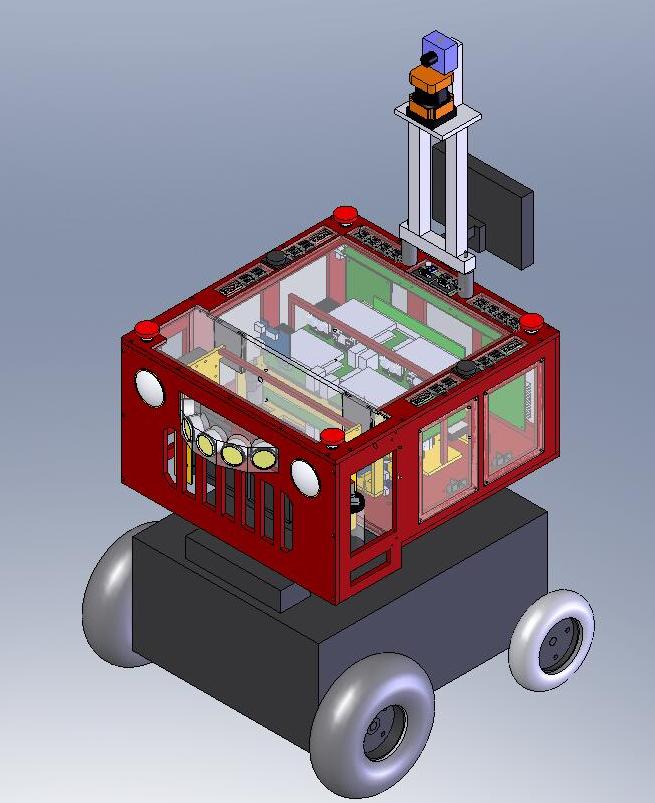

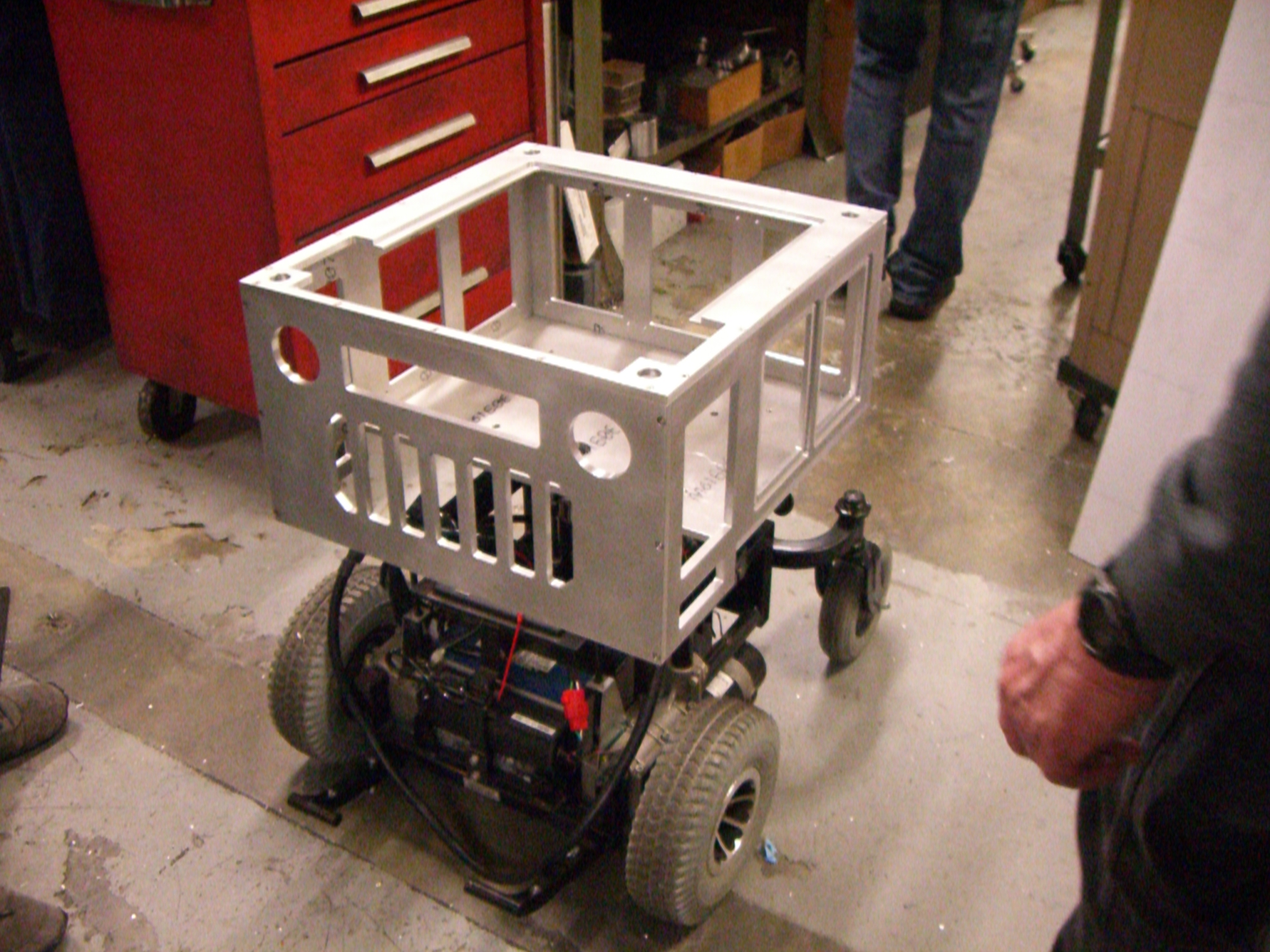

The mechanical system consists of locomotion, battery, cooling, and computer protection system.

It discusses the design decisions, part manufacturing, assembly, as well as testing.

It also includes integration issues between mechanical and electrical systems pertaining aspects such as:

* Making sure size (length, width, and height) of boards are accommodated.

* Specifying connectors and their placements so that they are easily reachable.

* Cable placements.

The to do section is an ongoing internal message board. The public section starts at right after.

We also add the cost section that details all the parts (machined by ourselves or purchased from outside) that are used.

To Do

Mechanical to do list, which also include fixed items. Note that there is also one in the electrical section.

Design and Implementation

The components can be divided to two: manufactured parts (such as shock-absorbing standoffs) or purchased parts. The manufactured parts in our robot are not too complex. In general they can be classified to the following 5 types:

- Flat thick (3/8”) aluminum pieces for the robot body. It needs to be milled for shape and window recesses, or drilled and tapped for holes (some has clearance for counter-bores) to connect all parts.

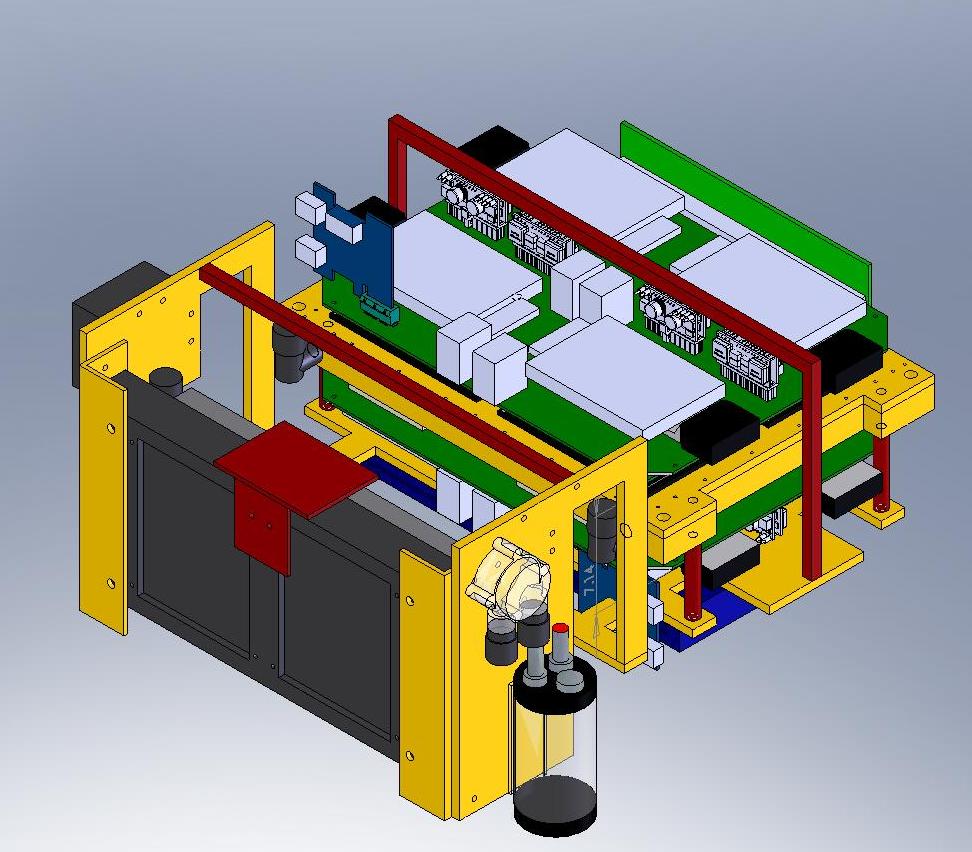

- 3/4” thick Aluminum cooling block. It needs to be milled for shape and water channels. There are also a few tapped holes to screw in the cooling block top to seal the water.

- Flat 1/4” aluminum pieces for a skeleton to connect the computer boards with the cooling system. No tapped holes.

- 4 smaller standoffs made from 3/8” diameter aluminum cylinder to connect the cooling block with the cooling system base.

- Acrylic Plastic panel for windows, as well as inside and top panel.

There are a few various manufactured parts (such as a few L-brackets) but they are easily machined in minutes.

We designed the robot parts using SolidWorks and the files are available below. The cost of SolidWorks is $160 for a one year license. We do not include this in the total cost because we provide all the .pdf drawings that can be given to a machinist.

There are different ways to machine if a lab cannot machine the parts in-house. One is to use an online service by emachineshop.com, the other is a local machine shop.

emachineshop.com can be quite affordable if all the pieces can be machined from one set up (the original setup is the most costly). This means that all parts are machined from the same material to be considered 1 jobs and save the cost. For our design, we have to do at least 5 jobs. The robot body and skeleton pieces can conceivably use the same aluminum thickness. However, the cooling block has to be done as a separate job. The windows can also be done by the supplier using custom service such as eplastics.com.

In total the cost would be about than $4000, this is quite competitive. If we assume a 20 percent raw material cost or $800 (quite high, material costs are usually nominal) and 160 hours of labor, this translates to hourly labor of $3200/160hr = $20/hr. Depending on the city machining labor can be as high as $55 - $65 per hour. The drawback is that the design has to be perfect. If there is a mistake, we have to correct it after-the-fact and this can be complicated if we want to salvage those parts.

With a local machine shop, it is possible to get valuable feedback from an experienced machinist as we are quite new in building custom robots. He/she can find a fatal flaw in the design during assembly (if the pieces don't fit together), or even before the machining process and suggest a solution. Waterproofing on the cooling block (keeping the water from spilling to the computers) is one system problem that we should pay close attention on.

We, on the other hand, have a great machine shop on the USC campus (led by Don Wiggins) that are priced competitively ($20/hour), because we are part of the university. So, for us there is no decision to make. This is the best option. We do not need to scout for an affordable, trustworthy, and skilled machine shop.

Just in case you can machine parts in your own lab, onlinemetals.com would be one supplier we suggest because it accepts small orders.

After all the parts are done, we anodize the aluminum with the USC colors: Cardinal (RGB 153,0,0) and Gold (255,204,0) at K&L Anodizing.

The full mechanical implementation is divided into the sub-systems below. However, in the following table, we list the cost accrued in manufacturing custom parts.

Note that using molded plastic is also another option (for example: Maggie): construction picture gallery.

Solidworks Model

Here is the BEOBOT2.0 ZIP FILE of all the Solidworks model part.

The main assembly file is “Robot Models/robot7.SLDASM”. A majority of the files is on the “Robot Models” folder. However, there are a few sub-systems that have their own folders:

- Baseboard: imported from Altium (converted from a STEP file to a SolidWorks assembly).

- Connectors: some are also imported from Altium.

- Cooling Board: imported from Altium.

- Encoder System: Not integrated with the main robot assembly because our Liberty 312 wheelchair model is a simplified one.

- Pico ITX: imported from Altium.

- Sensors: some are imported from Altium.

- Sonar: structure in front of the robot that holds sonars, cliff sensors, Laser Range Finder together.

The “Machining Files” folder contains pdf files of all the drawings.

Ignore the “OLD” folder.

Machining Related Cost

| Number | Item | Purpose | Cost | Count | Item Total | Supplier | Notes |

|---|---|---|---|---|---|---|---|

| 1 | Machining | Done in on-campus machine shop | $3857 | 1 | $3857 | Price (raw material and labor) depends on the machine shop | |

| 2 | Aluminum Anodizing | $112.50 | 1 | $112.50 | K&L Anodizing | look for local anodizing service |

The breakdown for total machine shop cost is $677 for material and $3180 (159 hours) for labor. Note that, if purchasing materials through machine shops, usually the cost is much lower because they purchase in bulk. Just as an unofficial tally: the material cost for the inner part of the robot (cooling system) is $113, while the robot body stock costs $564. The labor breakdown is: $2200 (110 hours) for the inner robot and $980 (49 hours) for the robot body.

The inner robot cost more (with respect to the robot body) in terms of labor because there are more parts (thus more setup time), while cost less for stock because most cooling components are purchased off the shelf (we only need to machine the structure that holds all components).

Mechanical Sub-systems

The mechanical sub-systems are listed below and the cost for each is itemized below. Note that the custom parts machining cost is bundled together and not included in the individual sub-system. <exttab2>

| Number | Sub-sytem | Cost | Notes |

|---|---|---|---|

| 1 | Machining | $3857 | Price (raw material and labor) depends on the machine shop |

| 2 | Locomotion | $360 | |

| 3 | Body | $0 | All cost are for machining parts |

| 4 | Cooling | $309.43 | |

| 5 | Shock Absorption | $7.76 |

Total System cost: $4646.69 NOTE: prices may change and shipping cost not included.

Locomotion

We use the Liberty 312 Wheelchair for the locomotion system. We take out the chair and feed the joystick control lines to our motor controller.

It's robust and has enough torque can carry up to 300 lb. Has two 12V 35Ah batteries and a built-in charger.

Note that the components and board for motor control are itemized and discussed in the electronic section.

Purchased Components

The following table itemize the components that are used in this sub-system: <exttab2>

| Number | Item | Purpose | Cost | Count | Item Total | Supplier | Notes |

|---|---|---|---|---|---|---|---|

| 1 | Power Wheelchair | Liberty 312 | $200 | 1 | $200 | Ebay | bought used from Ebay, just need new batteries |

| 2 | SLA Batteries | Powersonic 12V 35Ah (7.7”x5.2”x6.1”) SLA batteries | $80 | 2 | $160 | Battery Standard |

Manufactured Parts

None for this section. We have to drill a hole for encoder cables (for odometry) that come out of the back motor gearbox.

Robot Body

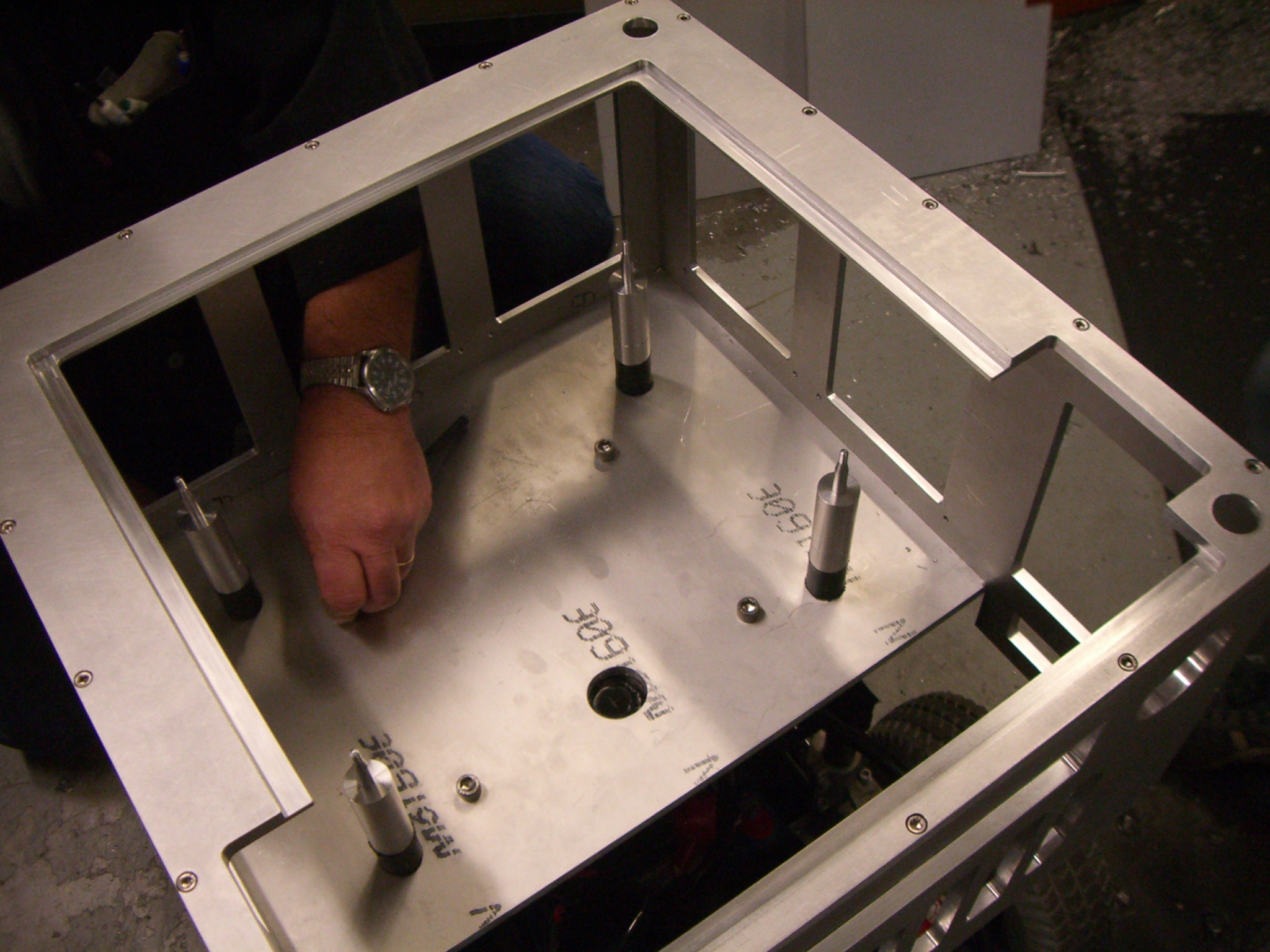

The Robot body is built with a 3/8” thick aluminum exterior. The computing module is placed inside a watertight room to avoid unwanted environmental interference such as dust and splashed water. In addition we build a platform on top of the robot to accommodate payload for sensors, robot arm, etc. We have plenty of killswitch mounting holes throughout the body.

Purchased Components

Total sub-system cost: $0

Manufactured Parts

The SolidWork parts and assembly is available in the SolidWorks Model section above. May need to add top panel handle (McMaster), plate & panel Lock System using ball lock pin: http://www.bigskyprecision.com/, http://www.pivotpins.com/ http://www.mjvail.com/KwikLok/RecessButton.html

Cooling System

We build our own water-cooling system. Each of the 8 computers have a heat spreader that is attached to the cooling block.

Purchased Components

The following table itemize the components that are used in this sub-system: <exttab1>

| Number | Item | Purpose | Cost | Count | Item Total | Supplier | Notes |

|---|---|---|---|---|---|---|---|

| 1 | Cooling liquid | Liquid Coolant Bottle, Low-Conductivity, 700mL (Colorless) | $19.99 | 3 | $59.97 | Koolance | |

| 2 | Angled Nozzle | Nozzle Pair, G 1/4” Swivel Angled for ID: 10mm (3/8”) | $14.99 | 2 | $29.98 | Koolance | Inner O-ring size,9.8mm ID,Width 1.9 |

| 3 | Straight Nozzle | Nozzle Pair, G 1/4” Compression for ID: 10mm (3/8”) | $8.99 | 1 | $8.99 | Koolance | Outer O-ring size,11mm ID,Width 1.5 |

| 4 | tubing | Tubing, Clear UV-Reactive PVC, 1ft/30.5cm ID: 10mm (3/8”); OD: 13mm (1/2”) | $1.29 | 16 | $20.64 | Koolance | |

| 5 | Pump | Pump 10mm, 3/8” ID | $75.95 | 1 | $75.95 | Koolance | |

| 6 | Flowmeter | $16.99 | 1 | $16.99 | Koolance | ||

| 7 | Reservoir | Bitspower Water Tank Z-Multi 80 Inline Reservoir | $36.99 | 1 | $36.99 | FrozenCPU | |

| 8 | Radiator | 2x120mm, Aluminum Vert. | $42.95 | 1 | $42.95 | Koolance | |

| 9 | Fan | 120x25mm | $7.99 | 2 | $15.98 | Koolance | |

| 10 | Liquid Funnel | $0.99 | 1 | $0.99 | Koolance |

Total sub-system cost: $309.43 NOTE: prices may change.

Manufactured Parts

The SolidWork parts and assembly is available in the SolidWorks Model section above.

Computer Shock Absorption System

For our shock-absorption system, the computing module is mounted on 4 shock-absorbing standoffs to withstand violent collision (in the rare event the robot goes out of control or something attacks it). Normally, like our laptops, the computers should be able to work despite vibration that comes from reasonable rough terrains.

Purchased Components

The following table itemize the components that are used in this sub-system: <exttab1>

| Number | Item | Purpose | Cost | Count | Item Total | Supplier | Notes |

|---|---|---|---|---|---|---|---|

| 1 | Shock Absorbers | 3cm MM 25mmRad | $1.94 | 4 | $7.76 | Vibration Mounts |

Total sub-system cost: $7.76 NOTE: prices may change.

Manufactured Parts

The SolidWork parts and assembly is available in the SolidWorks Model section above.

Future Additions

- Add 5 cm on, back, left, right of case to ease insertion of computer cluster

- plan for cable placements

- shock absorption posts need to be made easier for insertion

Back to main Beobot2.0 page